LEGO in the lab: creating the building blocks of life

31 January 2023

A 3D bioprinter constructed entirely from LEGO has been engineered by a team from Cardiff University to create affordable, scalable and reproducible tissue models.

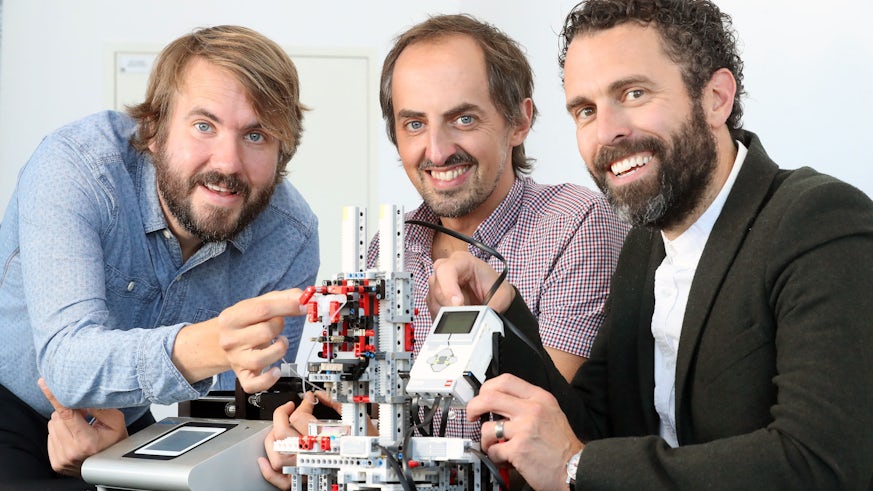

Imagined, designed and built by Dr Christopher Thomas, Dr Oliver Castell and Dr Sion Coulman from Cardiff’s School of Pharmacy and Pharmaceutical Sciences, the printer is capable of printing biological material – such as skin cells.

In contrast to much research which usually protects intellectual property, the Cardiff team have outlined the exact methodology used to engineer and build the device in the hope that their work can enable easy uptake, modification and improvement by other laboratories.

Dr Coulman said: “We set out to create a bioprinter that anyone can build, with minimal funds and that’s exactly what we have achieved. Our paper intentionally details every element of the build, including the specific LEGO parts used, as well as its capability, so that it can be easily replicated in any lab, anywhere in the world.”

Human tissue samples are needed for biomedical research to help advance scientific understanding of thousands of medical conditions as well as to develop effective treatments.

While 3D bioprinting offers hope for the development of these samples, it can be prohibitively expensive and off-the shelf devices can often be limited in their useability in the lab.

The Cardiff team hope that their LEGO 3D bioprinter could offer a technically proficient, scientifically robust, low-cost solution.

Using skin tissue as a mechanism to demonstrate the capability of the bioprinter, they have successfully printed hydrogel droplets containing cells. They are now in the process of recreating the three-dimensional architecture of skin.

Dr Thomas said: “At a time when research collaboration has never been more critical, and when research funding is so squeezed, we are proud to share an open source, accessible and affordable alternative to a much-needed piece of equipment that is beyond most researchers’ budgets.”

Dr Castell added: “We’ve demonstrated that, despite being constructed from an inexpensive and simple construction tool, this bioprinter is highly engineered and achieves the required level of precision to produce delicate biological material without any compromise in its performance.”

While the research is still in its infancy, it is hoped that in the future, the LEGO 3D bioprinter could help further our understanding of disease, contribute to tissue engineering and repair, and enable personalised medicine through the printing of cultured patient cells.

The Cardiff team is already undertaking further research to create viable skin models through the bioprinter which could be used to test treatments for skin disease and skin cancer, or to create skin grafts to replace damaged skin.

Speaking about the next stage of the project, Dr Castell said: “As with all 3D bioprinting, there are more studies to be done to look at developing the cell compatibility and viability of bio-inks. By making our printer readily available, we hope researchers will adopt this technology to share expertise and develop the model with additional LEGO components for the benefit of the entire biomedical research community.”

Matthew Patey OBE, CEO of British Skin Foundation, the charity who funded the research said: “We are delighted to see that the funding from the British Skin Foundation has allowed for such fantastic results with this novel research. We are looking forward to seeing how the research will now be used to progress the future of biomedical research.”

The full paper Development and Evaluation of a Low-Cost LEGO® 3D Bioprinter: From Building-Blocks to Building Blocks of Life is published today in the journal Advanced Materials Technology.