AI helps optimise power electronic converters

9 November 2022

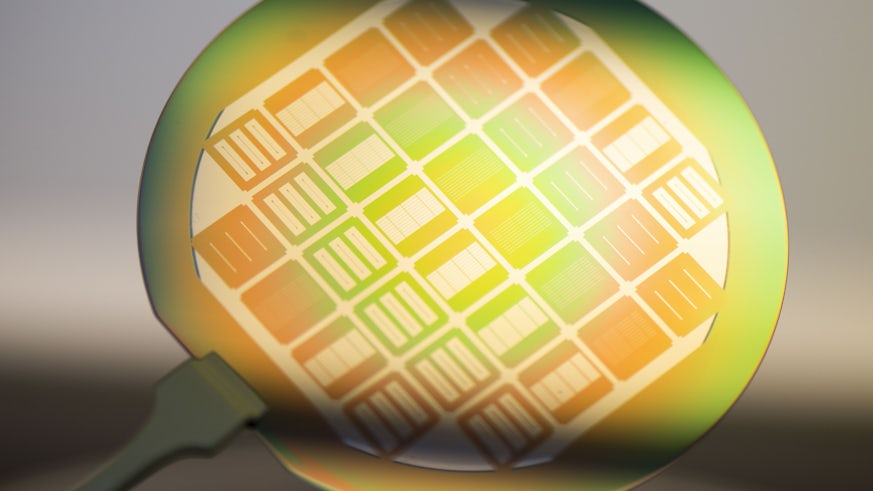

A new and more efficient way of modelling and designing power electronic converters using artificial intelligence (AI) has been created by a team of experts from Cardiff University and the Compound Semiconductor Applications (CSA) Catapult.

The method has reduced design times for technology by up to 78% compared to traditional approaches and was used to create a device with an efficiency of over 98%.

The team’s findings have been published in the IEEE Open Journal of Power Electronics and IEEE Transactions on Power Electronics.

A power converter is an electrical device for converting electrical energy. It can convert alternating current (AC) into direct current (DC) and vice versa or change the voltage or frequency of a current.

Power converters are used in a wide range of technologies, from mobile phones, computers and televisions to renewable energy and electric vehicles.

Existing methods of designing power converters largely rely on complex mathematical models which significantly increase the computational time and complexity of the design process.

A well-designed power electronic converter must have high efficiency, small volume, be lightweight and have low cost and low failure rate.

Therefore, the main goal of a power converter design method is to identify the best trade-off among these performance indicators.

In their study, the team explored a new design method using a type of AI known as artificial neural networks (ANN), which uses algorithms and computing systems that mimic the interconnected neural networks of the human brain.

The ANN was trained on an existing dataset of over 2000 designs, so the team were able to select the most appropriate design for their desired efficiency and power density.

The team selected four major components for the ANN-based design, including the power gallium nitrate (GaN) field-effect transistors (FETs), inductors, capacitors, and heat sinks.

The design approach was validated through experimental tests on a GaN-based single-phase inverter that was created using the specified design. The efficiency and power density of the device was well matched to the design and within the range of existing devices, making it technically competitive and commercially viable.

Co-author of the study Dr Wenlong Ming, Senior Lecturer at Cardiff University and Senior Research Fellow at CSA Catapult, said: “Accurate and fast transient modelling/simulation approaches are essential to efficiently and to rapidly optimise the performance of wide bandgap power electronics systems. We are delighted to work together with CSA Catapult to address this gap.”

Co-author of the study Dr Ingo Lüdtke, Head of Power Electronics at CSA Catapult, said: “Automated power electronics design optimisation enables the full exploitation of wide bandgap power semiconductor advantages when compared to their silicon counterparts. We are excited to be working with Cardiff University in this innovative area.”

CSA Catapult's Power Electronics laboratory is one of the UK’s most advanced to enable innovation through comprehensive modelling, characterisation, integration and validation facilities for power converters with higher efficiency and reliability with reduced size, weight and system cost.

Cardiff University has a growing international reputation for expertise in compound semiconductor electronics. It is home to the Institute for Compound Semiconductors, based at its new Translational Research Hub on Cardiff Innovation Campus. The University is a founding member of CSConnected and the Compound Semiconductor Centre, working closely with a range of organisations including the CSA Catapult.

Share this story

The School has world leading research, strong links with industry, and a friendly and supportive teaching environment make us one of the leading engineering schools in the UK.