Partnership develops chips for electric vehicles

10 February 2021

The Compound Semiconductor Centre (CSC) and Newport Wafer Fab (NWF) have been awarded UK Research and Innovation funding to develop advanced components for longer range Electric Vehicles (EVs).

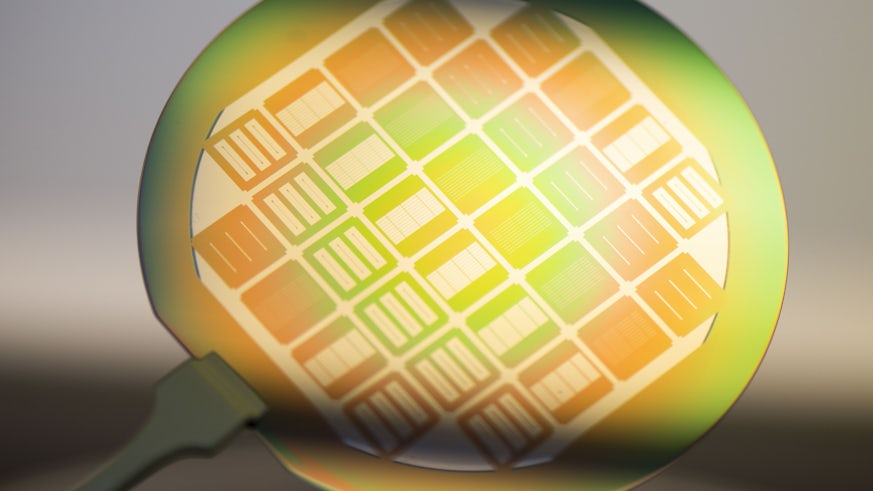

CSC – the joint venture between Cardiff University and IQE Plc – is teaming with NWF to create new production processes that will deliver high voltage semiconductor chip technology.

The new fabrication process, using gallium nitride on silicon (GaN on Si), will leverage more than 30 years’ experience in manufacturing silicon chips for power conversion at Newport Wafer Fab.

The Newport facility – the world’s first integrated Silicon and Silicon-on-Compound Semiconductor Foundry - is already accredited to supply its products to the global automotive industry. It is the UK’s largest semiconductor manufacturing plant, employing 450 staff.

NWF will use unique wafer processes developed by CSC in partnership with its parent company IQE at its Cardiff facility.

CSC recently achieved full ISO9001 accreditation of its internal Quality Management System covering development through to volume scale up.

The project is supported by UKRI under the ‘Automotive Transformation Fund: moving the UK automotive sector to zero emissions.’

Sam Evans, NWFs Director of Quality and External affairs, said: “This is an exciting step towards our vision of becoming a major manufacturer of Compound Semiconductor-on-Silicon products. We see the power components market as an excellent area to address in our plans to expand our current manufacturing footprint of 8,000 to 14,000 wafer starts per week.”

Rob Harper, GaN programme manager at CSC, added: “The GaN power chip market is expected to exceed £0.5Bn by 2025 with massive future growth opportunity for adoption in EVs. We are collaborating with global power semiconductor partners to help steer the process roadmap.”

Dr Wyn Meredith, Director of the CSC, commented ’This is an excellent example of two partners in the South Wales semiconductor ecosystem building on their respective technology and manufacturing strengths to offer advanced, next generation foundry services to the global semiconductor industry.

“Already this year we have seen the automotive industry output constrained due to a worldwide shortage in semiconductor chips with Volkswagen, Ford, Subaru, Toyota, Nissan, Mazda, Fiat Chrysler all reporting an impact to production, including temporary factory stoppages. Increasing Electric Vehicle demand will exacerbate such supply issues, so there is a huge opportunity to capture more market share for the Welsh Semiconductor Industry.’

Founded in 2015, the Compound Semiconductor Centre aims to accelerate commercialisation of CS materials and device research, realising a tangible economic return on UK investment. It is a key player in CSconnected – the world’s first Compound Semiconductor cluster based in South Wales.

Share this story

The institute provides cutting-edge facilities to help researchers and industry work together.