Ground breaking synthesis of the rare mineral georgeite leads to better catalysts

29 February 2016

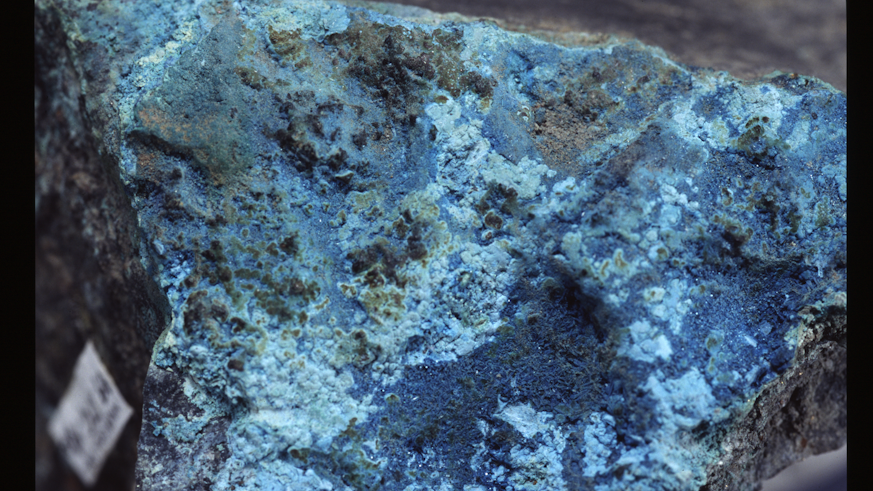

An extremely rare mineral, found only in two locations around the world, including an old copper mine in Snowdonia, has been made synthetically for the very first time by researchers at Cardiff.

Largely neglected up until now, the mineral, known as georgeite, has shown remarkable catalytic properties and could lead to improved methods for manufacturing some of the most important products in the chemical industry. The work is published this week in the journal Nature.

The team, based at the Cardiff Catalysis Institute in the School of Chemistry, has shown that georgeite is an extremely efficient catalyst in the process used to produce hydrogen from water by the water gas shift reaction. Hydrogen is an essential ingredient used to manufacture methanol and ammonia, which form the basis of hundreds of chemicals including fuels, plastics, paints, solvents and fertiliser.

Georgeite belongs to a family of minerals known as copper hydroxycarbonates that are widely used as catalysts in the chemical industry.

Whilst researchers are familiar with other minerals in this group, such as malachite, aurichalcite and rosasite, little is known about georgeite due to its exceptional rarity, low purity, instability and highly disordered nature.

For the first time, the team have successfully synthesised georgeite in the lab in large quantities and in its purest form – in nature it is only found as impure deposits.

They did so using a technique known as supercritical anti-solvent precipitation (SAS), which involves the creation of a solid material from a liquid solution. The starting material, otherwise known as the precipitating agent, was supercritical carbon dioxide – a form of the well-known gas.

The resulting mineral, which was rapidly made, had a highly amorphous structure which contributes to its high activity when it came to catalysing reactions.

Professor Graham Hutchings, Director of the Cardiff Catalysis Institute, said: “We have shown that we can make large quantities of material that has historically been known as a very rare material.

“Furthermore, we’ve discovered the conditions to make a very pure version of this mineral fairly easily, whereas in nature it is only found as impure deposits.”

Professor Hutchings and his team tested the catalytic ability of georgeite against commercially used catalysts in the water-gas shift reaction – an extremely important process in the chemical industry in which water reacts with carbon dioxide, in the presence of a catalyst, to produce hydrogen.

“We found that the georgeite was a superb catalyst in the water-gas shift reaction, and had a much higher performance compared to the commercial catalyst that is currently used in industry,” continued Professor Hutchings.

The team also included researchers from the UK Catalysis Hub, University College London, Diamond Light Source, University of Liverpool, Technical University of Denmark, Lehigh University and Johnson Matthey.